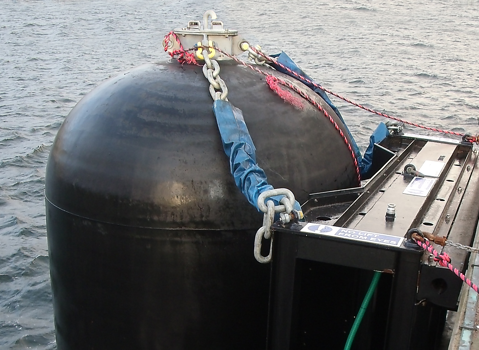

Yokohama hydro-pneumatic fenders deliver enhanced protection, allowing safe moorings for submarine or other sub-surface berthing applications.

James Fisher Fendercare’s (JF Fendercare) Yokohama hydro-pneumatic fenders are designed to provide full protection and enhanced reliability at surface and subsurface, enabling safe moorings for submarine or other sub-surface berthing applications.

The advantages of hydro-pneumatic fenders over alternative, traditional berthing methods include:

- Cost-effective replacement for deep water catamarans

- Easily moved to provide flexibility in berthing

- Easily transported to provide emergency berthing facilities

- Maintenance requirements almost non-existent

- Unaffected by extreme climatic conditions

Submarine fenders

As the trusted solution for submarine berthing, hydro-pneumatic fenders are extensively used by navies across the world.

To maintain their position hydro-pneumatic fenders are deployed vertically and are water ballasted to suit the hull shape and freeboard. A counterweight is attached to the fender’s base for stability, of which the weight, shape, and method can be adjusted to suit specific requirements.

JF Fendercare has supplied Yokohama submarine fenders to many navies around the world, including those of Australia, Brazil, Canada, Greece, Japan, the United Kingdom, and the USA.

Hydro-pneumatic fender features

Hydro-pneumatic fenders are designed to offer higher bursting strength than a normal surface fender, with the minimum burst pressures being:

- 2000mm diameter and smaller = 4.9kgf/cm2

- 2500mm diameter and larger = 5.7kgf/cm2

To facilitate water charge and discharge, flange openings are sited at each end of the fender. In addition, the fenders are fitted with a safety valve to enable excess pressure to be released should over compression occur.